Air-Sprung Fox 40 Float RC2 Fork

Fox Racing Shox has all but ditched coil springs in favor of a new air-spring system that it developed over a two-year period, first in the original 40 chassis and later, inside the new, lighter-weight RAD chassis that made headlines when it debuted at the 2012 Leogang World Cup. Is it good? Fox reported that in its early development, some of its female racers switched back to coils until Fox could tailor its negative spring system to lighter weight riders, but since then, none of its riders have gone back – and the heresy continued as Fox announced that only its ‘entry-level’ OEM 40 will retain the coil spring, and with the addition of new lowers, the Air 40 will be ready for this season’s onslaught of 650B DH bikes. The Air 40 is presently in production, it weighs 5.98 pounds and with the steerer tube cut for a direct-mount stem, it is 521-grams (1.15 pounds) lighter than its predecessor. Its official name is ‘Fox Factory 40 Float RC2’ and it’s not going to be cheap. Fox pegs the MSRP at $1700 USD. They will be in stores this summer.

Fox 40 Float RC2 Highlights:

• Travel: 203-millimeters (8 inches)

• Adjustable air spring system with titanium coil-type negative spring

• Air-volume adjustment feature to control end-stroke spring rate

• RC2 damping system

• Lighter weight: 482 grams less than 2012 40 (521g w/direct-mount stem)

• All new chassis: Taper-butted stanchions, new lower casting, new crown design

• Air-bleed buttons on sliders to equalize internal fork pressure

• Kashima coated stanchions and RC2 damper shaft

• Low-Friction SKS seals throughout

• Post-type caliper mounts

• Wheel options: 26 or 27.5-inch wheels (different sliders)

• Stated weight: 5.8 pounds

• MSRP: $1700 USD

• Available: Summer 2013

Pressurizing the fork’s air spring pushes on the white seal head upper left)

and completely compresses the blue titanium negative spring. RC photo

Two key elements that Fox engineers developed for the new 40’s air spring make its action equal to and in most cases, superior to a coil-sprung fork. The first is an advanced negative spring system that employs a long, titanium coil-spring. Air-type negative springs release abruptly in the first 15-percent of the fork’s stroke, but the linear rate of the titanium spring creates a seamless, soft-release of the air spring at 50-percent of the fork stroke. Negative springs will be sold in four levels of stiffness, but the medium, green-colored spring that will ship with the Air 40 is reported to be perfect for almost everyone. Most of Fox’s elite racers are on the green spring.

|

Want the feel of the original 40? Simply set the spacers to raise the volume-adjust piston as high as it goes and it will emulate the linear compression rate of a coil spring. |

To cause the fork spring to be more progressive, unscrew the retaining bolt

at the end of the shaft lower right) and lower the piston by rearranging some

of the eight spacers on the shaft. RC photo

The second half of the Fox 40 air spring system is a simple volume-adjustment piston assembly that sits beneath the left-side top cap. By switching spacers to change the location of the piston on the shaft, nine volume options are possible. Want the feel of the original 40? Simply set the spacers to raise the volume-adjust piston as high as it goes and it will emulate the linear compression rate of a coil spring. A more progressive spring rate is accomplished by lowering the volume-adjust piston. The progressive option allows the 40 to be sensitive over the chatter, which greatly improves traction, yet still firm enough at full compression to eliminate bottoming during maximum events. Switching out the negative spring requires dropping the lowers from the fork, but adjusting the air volume stack can be done in ten minutes by removing the left top cap.

Anti-Friction Strategies

Seal friction is always a detriment to air-spring systems, and Fox has paid particular attention to eliminate it. The 40 chassis has room for a large-volume air chamber, which reduces the pressure necessary to suspend the rider and puts less squeeze force on the seals. Only 70 psi is required to suspend a 200-pound rider and the pressure range between the heaviest and lightest riders is 45 to 80 psi. Fox uses the slippery Kashima coating on the stanchion tubes as well as the shaft of the RC2 damper cartridge, and

Suspension Product Manager Bill Brown said that all of the seals are specifically engineered for the 40 by SKS, in collaboration with Fox to minimize friction.

Damping Improvements

Damping forces are still controlled by the RC2 damping cartridge. Because the air spring system can better resist bottoming, the hydraulic bottom-out function has been eliminated from the new damper which, beyond its new seals and slippery Kashima-coated shaft, remains essentially unchanged from the 2012 40. All of the damping adjustment dials are their familiar places. Compression damping has been adjusted to be lighter because the new spring system takes away much of the damper’s workload in the second half of the fork’s stroke.

Chassis Redesign

Fox had ten years to find ways to improve its flagship DH fork, but beyond the slenderized magnesium lowers and a couple of air-relief buttons, the Air 40 appears at first glance to be nearly the same as its predecessor. However subtle, every component of the new chassis is essentially a new part. Fox says it took something from almost every component of the fork to achieve its remarkable 512-gram weight reduction. Many changes in the chassis, however, were instigated to create some flex in the 40, which has been criticized for its rigid ride over chatter sections.

|

However subtle the changes may be, every component of the new chassis is essentially a new part. |

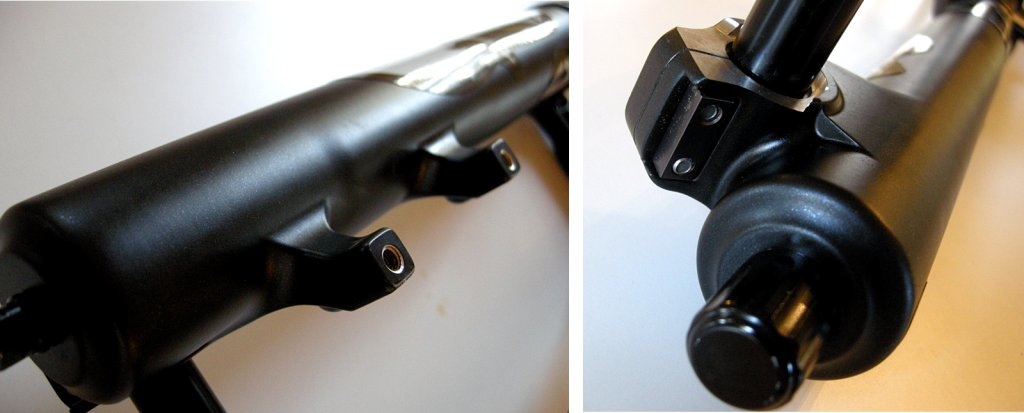

Crowns: In its quest to reduce weight, the cavities under the upper and lower crowns have been redesigned to eliminate X-webbing and the stanchion clamps have been reconfigured with thinner sections near the tubes to prevent stress risers from forming. The clamp-bolts have been moved to the front and the clamp-angles have been reconfigured to improve grip while using less material. Fox anticipated that some racers will use a splash guard, so it added threaded bosses on the underside of the lower crown.

Taper-butted stanchion tubes: Air-pistons sliding up and down inside the left stanchion tube required an ID as smooth as the tube’s OD. The Kashima-coated tubes are tapered internally to be thicker near the lower fork crown. The tubes are tapered thinner both above and below the lower crown, which encourages the stanchions to flex a little. This gives the new 40 a welcome degree of comfort over the original. Both the right and left stanchions are the same, and the internals of the original will retrofit into the new chassis.

Pressure-relief valves: Downhillers who regularly bled the fork’s internal pressure by slipping a zip-tie between the fork seal and the stanchion tubes will no longer have to risk damaging the seals of the 40. Pressure relief buttons on the back of each slider are provided to equalize the fork’s internal pressure, which can be three PSI higher at the top of some uplifts due to the lower ambient pressure at altitude. Fox showed a cross section of the fork seal to illustrate how a minor increase in air pressure inside the fork can impart significant squeeze force on the stanchion tubes. Internal pressure buildup can also be caused by off-gassing of the suspension lubricants, or by an increase in temperature, so Fox recommends pressing the buttons before altering the spring or damping settings, and before the start of each DH run.